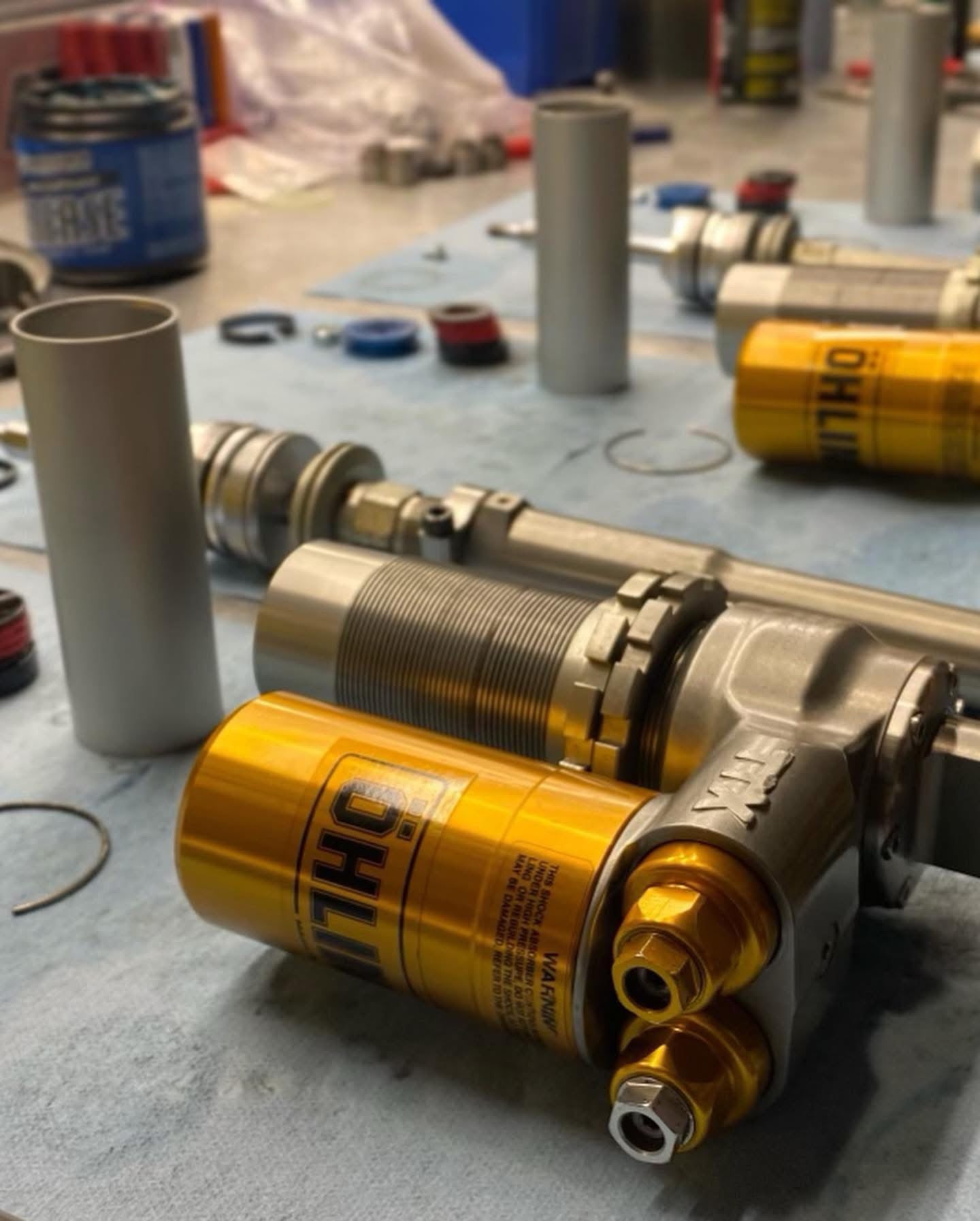

Custom Damper Builds

Do you have a one off or unique project?

The custom build process is frankly very selective for us. We need to make sure this is a good fit for the sake of cost, time invested and ideal outcome. We are constantly working to improve efficiency for these projects to allow more interesting things to be accepted into the Inertia Lab portfolio.

What is the process?

Contact us! It will be necessary to establish a budget, timeframe and overall goal. Once we know a bit more about your project we can start to set expectations and create a job to move forward.

Are there any limitations?

Yes, we need to be able to package your setup within the TTX or TTR architecture. If you have a damper that is too short or has requirements outside the scope of that product line we will not be able to make a setup for you. That being said most arrangements can be accommodated.

Why just the TTX/R?

There are a few pieces to this equation:

- The components in the TTX/R line are the high end of the market in quality and performance. They allow so much variability in construction (accepting custom designed components where necessary) and valving (allowing total control of curves without any concern for cavitation).

- The parts availability, inventory data, control of timelines and control of specification we have without even needing to contact Ohlins is nearly total. We have complete authority over the build without requiring manufacturer input or scheduling.

- The necessary time investment in doing this work aligns with the cost and component quality of the TTX/R parts. This allows us to retail the value of our time when quoting out a project. It is not cheap and we make no apologies for that fact, but the results are highly focused, extremely effective and exclusive.